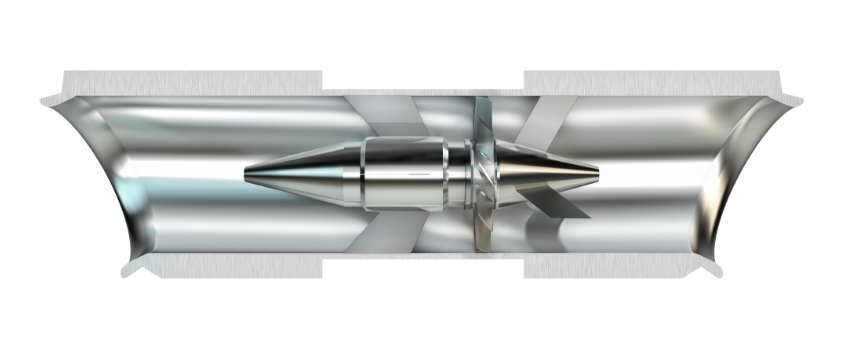

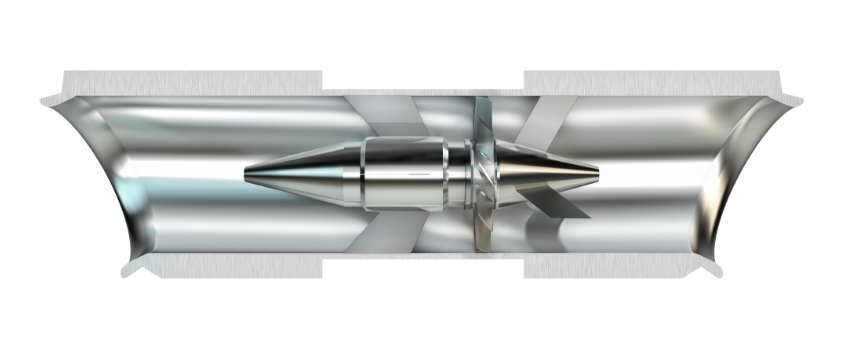

None of these drawbacks are present with the MoJet®, which is the most modern jet fan technology available for enhancing in-tunnel thrust.

View our technical paper on jet fan technology

Discover the benefits of the MoJet®

The reversible MoJet® tunnel ventilation system can increase the in-tunnel aerodynamic thrust by up to 100%